Allgemeines

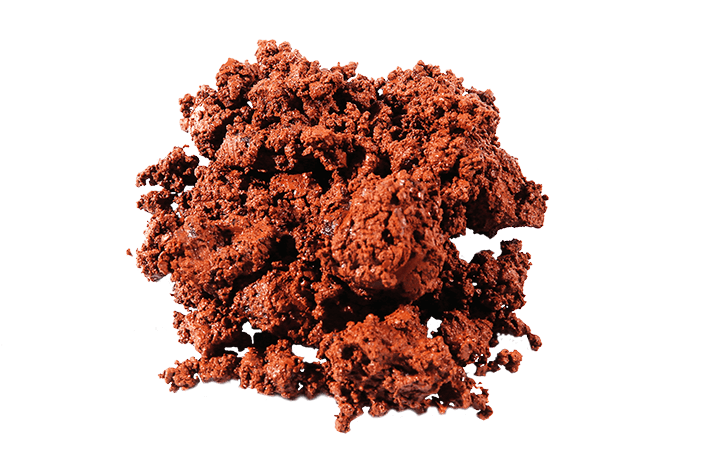

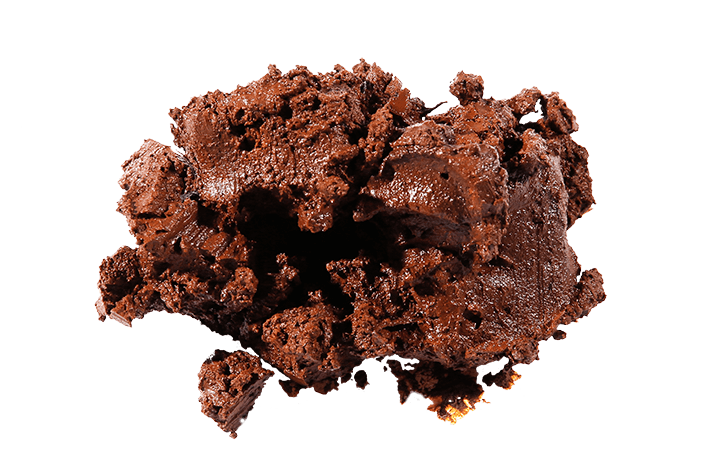

Ferrosorp® DG-Produkte sind pulverförmige Reaktionsmittel und erdige, bzw. thixotrope Nassschlämme auf Basis von Eisenhydroxid, welche den bei der anaeroben Vergärung in Biogasanlagen entstehenden Schwefelwasserstoff (H2S) bereits im Gärsubstrat binden.

Nachgeschaltete Entschwefelungstechniken, z.B. biologische Luftentschwefelung oder Aktivkohle, lassen die Entstehung von H2S zunächst zu, obwohl nachgewiesen ist, dass H2S einen hemmenden Einfluss auf die Methanogenese hat und Spurenelemente durch hohe Sulfid-Konzentrationen im Gärmedium ausgefällt werden.

Aus unserem großen Produktportfolio von derzeit 7 verschiedenen Spezifikationen ermittelt unser Fachpersonal das bestmögliche Entschwefelungskonzept für die Anforderungen Ihrer individuellen Betriebsbedingungen.

Ihre Vorteile

Anwendungsgebiete

Anwendung

Die Zugabe von FerroSorp® DG erfolgt in Biogasanlagen am einfachsten zusammen mit den Gärsubstraten

(z.B. Feststoffdosierer).

FerroSorp® DG kann als alleiniges Entschwefelungsmittel verwendet werden, stellt jedoch auch eine optimale Unterstützung von Luftentschwefelung oder Gasreinigungsprodukten, wie beispielsweise FerroSorp® S oder Aktivkohle dar.

Lieferformen & Verpackungseinheiten*

*Bitte beachten Sie, dass produkt- oder produktionsbedingt abweichende Verpackungsformen & -mengen erforderlich sein können.

×